| Build Thread, Page :

<< 9 10 11 12 13 14 15 (284 posts, 20 posts per page, 15 pages in total)

|

[ < Prev ] |

| David Duckett, Image # 21623 | 13 Mar 11 12:20 |

I used an x-acto knife to remove the wood panels between the stringers, (top). I then glued in another piece of balsa cut on a bevel to fit against the front former. I used sandpaper glued to a piece of wood the same size as the opening to sand the rear smooth with the back former. Finally I glued triangular pieces of 1/32" balsa at the top and bottom of the openings. Easy. |

| jerry campbell, Comment for image # 21622 | 13 Mar 11 09:24 |

| Would sure be nice if you showed how you carved these ports, showing the tool you used and how you used it. Great start to this project. |

| John M Oshust, Comment for image # 21622 | 13 Mar 11 09:09 |

| I get it...triple exhaust vents on the port side, just left of the air intake. |

| David Duckett, Comment for image # 21622 | 13 Mar 11 08:08 |

| No, they're ports, as well, and there are three, too. The cowl has been sanded to shape. |

| moostang51, Comment for image # 21622 | 13 Mar 11 06:34 |

| Would the right side be exhaust "starboards"? |

| David Duckett, Image # 21622 | 13 Mar 11 06:18 |

Exhaust "ports" added to the left side. The right side has them. also. |

| David Duckett, Comment for image # 21583 | 11 Mar 11 17:43 |

| You're correct. |

| moostang51, Comment for image # 21583 | 11 Mar 11 17:38 |

| Having never built a laser cut kit other than the "on hold" TF Spitty, it seems that the burned edges of the formers would provide a great reference gauge when sanding and shaping. I like how the rudder is already incorporated in the fuse construction. |

| JohnG., Comment for image # 21583 | 11 Mar 11 12:42 |

| Very very nice...well done...as usual. |

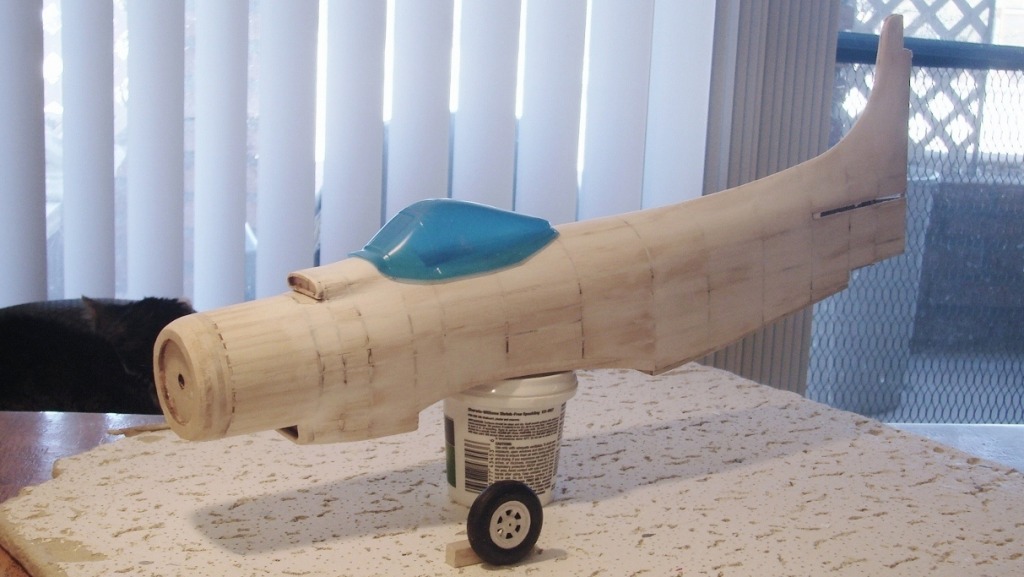

| David Duckett, Image # 21583 | 11 Mar 11 10:49 |

Sanded with 320 wet/dry sandpaper.Shaping of the cowling is next and then detail the two scoops before another coat of filler. |

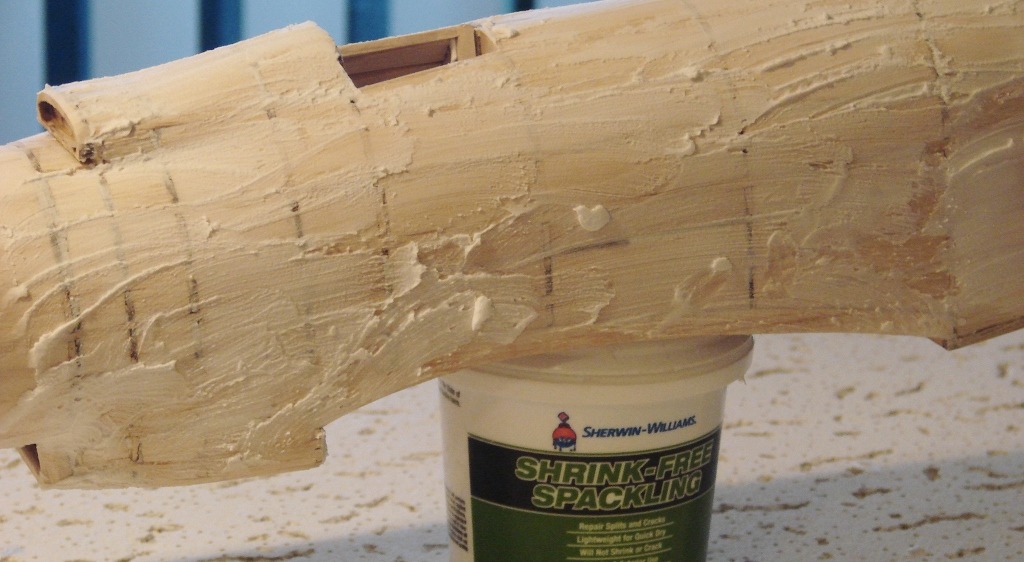

| David Duckett, Image # 21582 | 11 Mar 11 10:47 |

Filler by finger and let dry 45 minutes, about 10% humidity currently. |

| David Duckett, Image # 21581 | 11 Mar 11 10:45 |

Holes have been filled with glue and it's ready for some filler. |

| David Duckett, Image # 21580 | 11 Mar 11 10:43 |

Bottom air scoop is formed with two pieces. |

| David Duckett, Image # 21579 | 11 Mar 11 10:42 |

I used 3/32" and 3/16" good balsa for the fill. |

| Dfell, Comment for image # 21526 | 08 Mar 11 05:05 |

| This photo of yours and Nigel's (Roring40) one really shows the technique of filling in and answers a lot of my previous question to you. Obviously the sanding is critical, not to sand too much. |

| David Duckett, Image # 21526 | 08 Mar 11 00:00 |

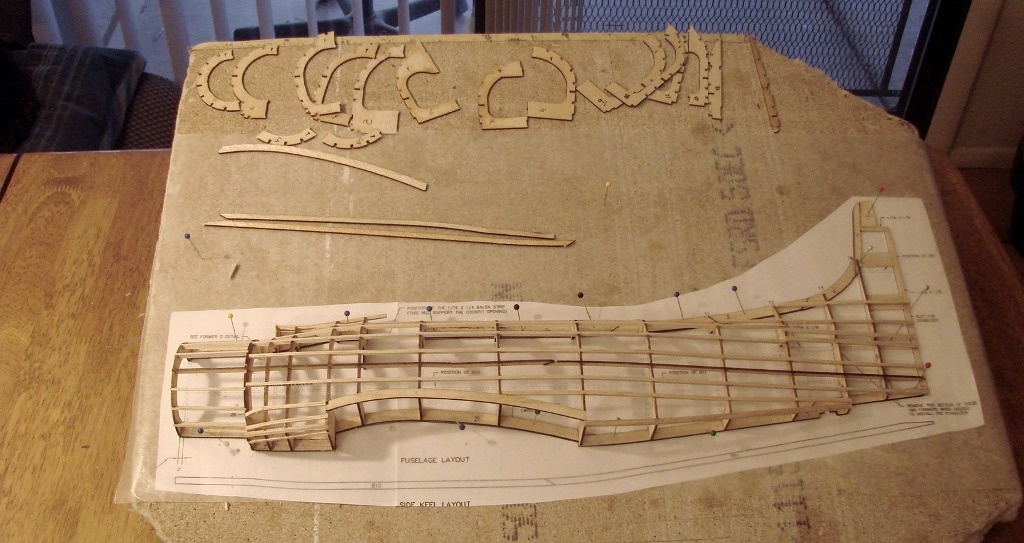

Fill 'n sand |

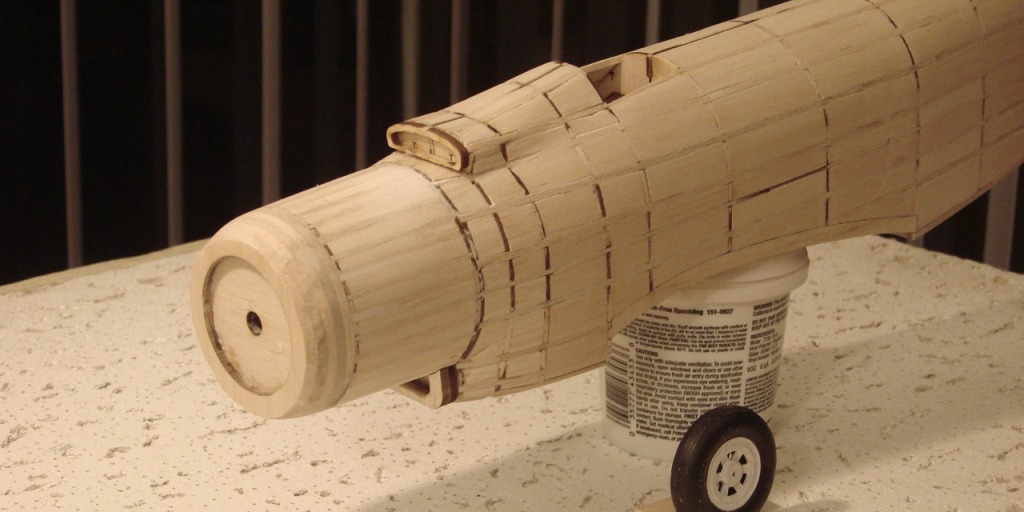

| David Duckett, Image # 21525 | 08 Mar 11 00:00 |

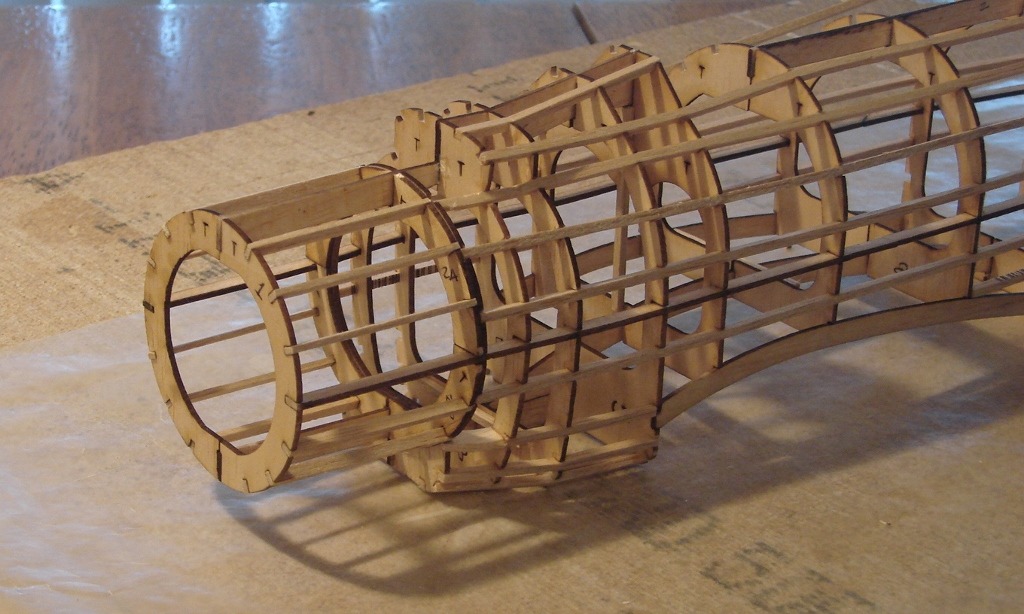

I doubled the stringers for the nose section. Six pieces of 1/8" stock for the cowling. |

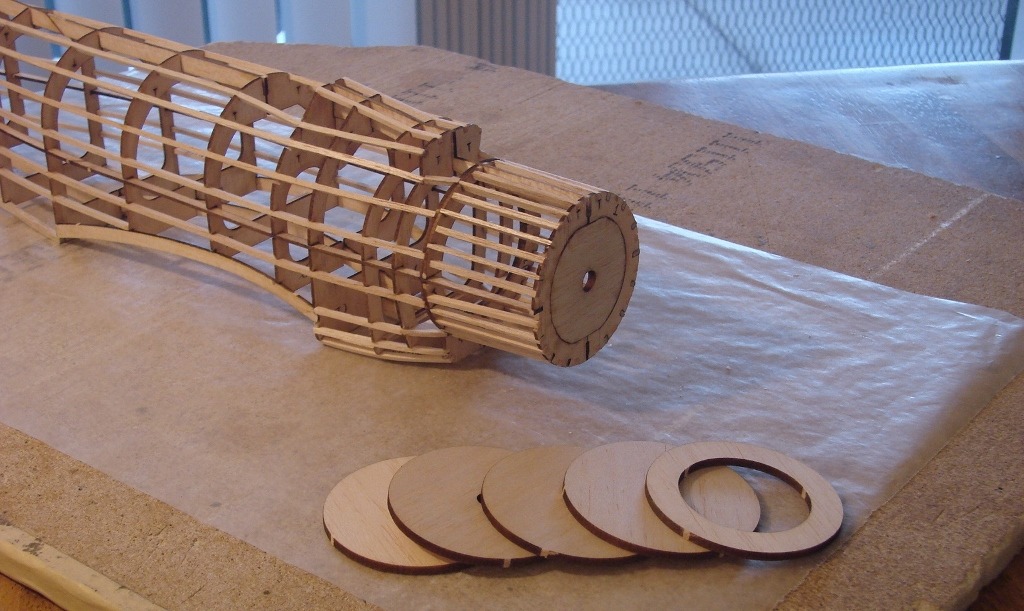

| David Duckett, Image # 21524 | 07 Mar 11 23:58 |

I'm using 3/32" stringers for the main construction. The front uses 1/16" x 1/8" strips. |

| David Duckett, Image # 21523 | 07 Mar 11 23:56 |

While waiting for coaming, Ive started the 1st Skyraider. |

| David Duckett, Image # 21326 | 25 Feb 11 07:35 |

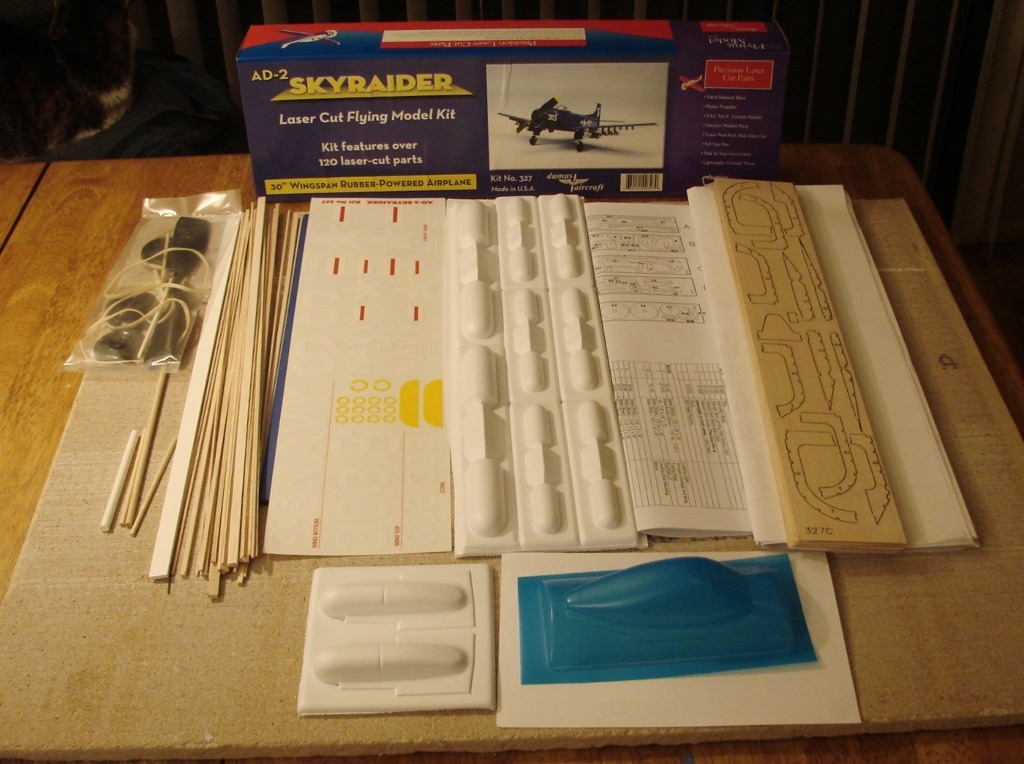

Kit contents. Looks a bit shy on wood ? We'll see. |

| Build Thread, Page :

<< 9 10 11 12 13 14 15 (284 posts, 20 posts per page, 15 pages in total)

|

[ < Prev ] |