| Build Thread, Page :

1 2 3 4 5 [ 6 ] 7 8 9 10 11 (212 posts, 20 posts per page, 11 pages in total)

|

[ < Prev ] [ Next > ] |

| Don C, Comment for image # 35625 | 22 Feb 16 21:25 |

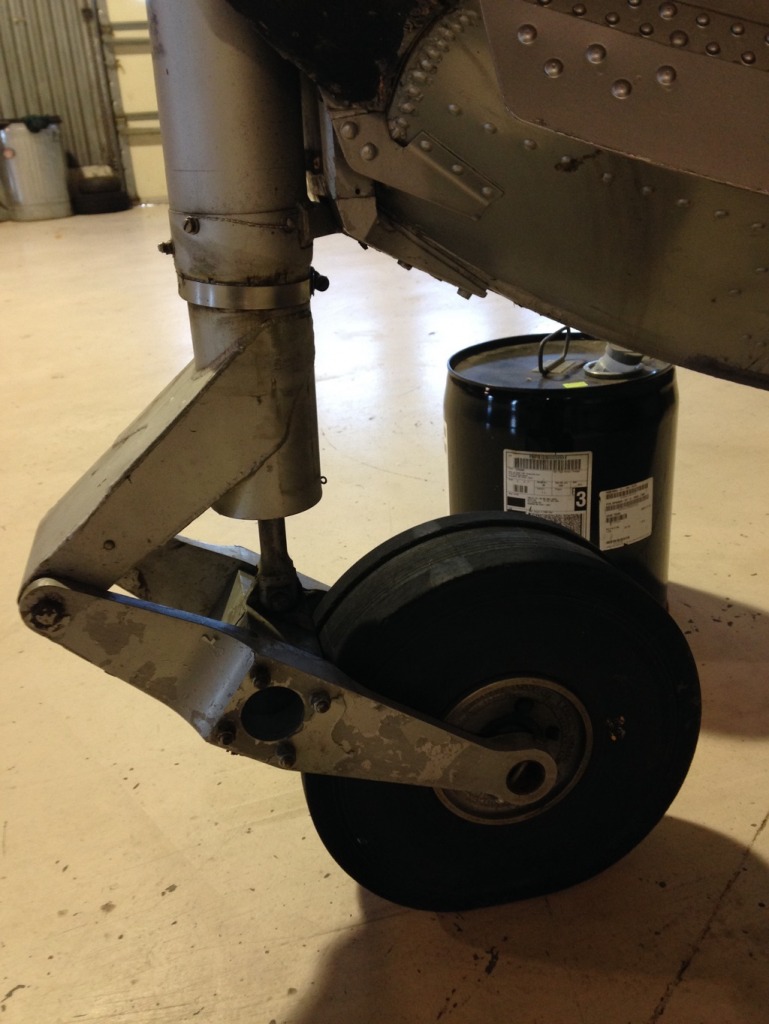

| Thanks, Sky. The wheel picture was taken by one of the gentlemen who care for 4932 out in Maine. By the way, the wheel(s) came from Guillow's. No bill. That was nice, but they were the wrong size, so I made one. |

| Don C, Image # 35640 | 22 Feb 16 21:22 |

Progress report, I guess. Plane and floats are getting done separately.Then the cables and bracing can be added. Think I'm going to skip the float rivets. |

| Skyediamonds1985, Comment for image # 35625 | 22 Feb 16 20:44 |

| Fantastic detailing Mr. Don. Very good attention to the details. Wish I had a vertical lathe, but I'll vicariously enjoy yours until then. By the way, excellent close up of the wheel of the real float to the DHC-2. |

| Don C, Image # 35625 | 22 Feb 16 20:12 |

The result. 1/4" dowel on Ohurst bearing. |

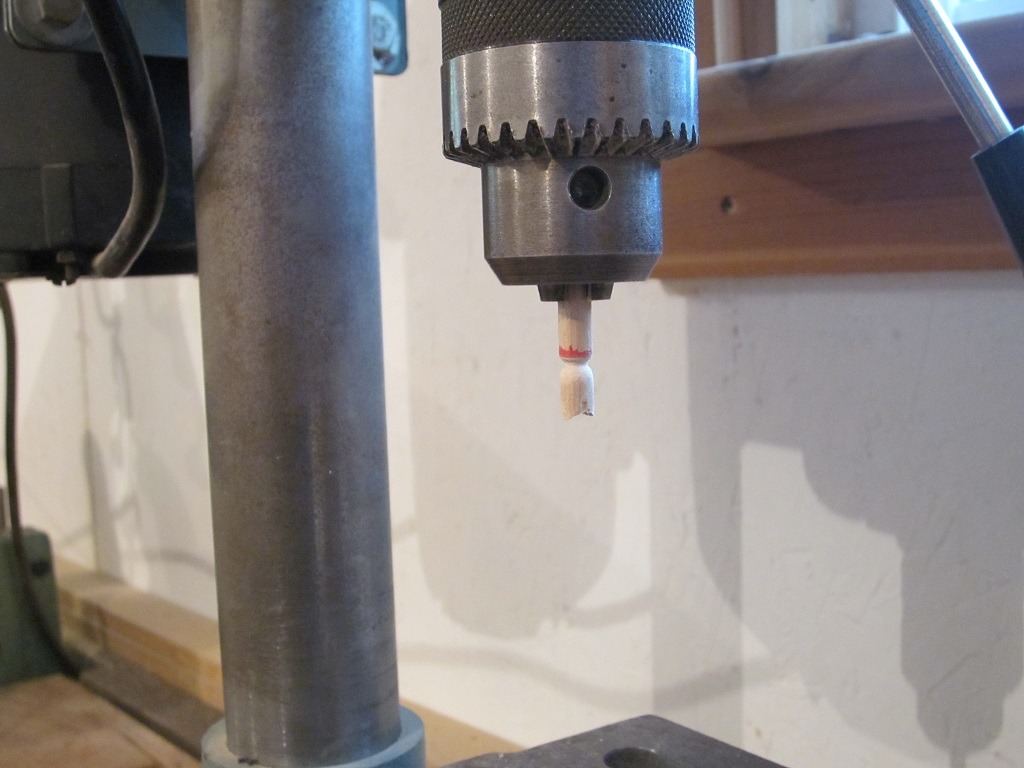

| Don C, Image # 35624 | 22 Feb 16 20:08 |

shaping spinner on my "vertical lathe". |

| Don C, Comment for image # 35592 | 14 Feb 16 12:08 |

| These taste the same, except that the drumsticks and thighs are as tough as a rubber tire. The one displaying in the back is the old tom and the others are last year's hatch. Typical teenagers, got to prove who's toughest. |

| David Duckett, Comment for image # 35592 | 14 Feb 16 06:30 |

| The only time I've ever seen turkeys that close was at Safeway. |

| Don C, Image # 35592 | 13 Feb 16 16:43 |

Never seen a turkey fight before. |

| Don C, Comment for image # 35489 | 13 Feb 16 16:27 |

| Sky-The stuff I used is from Plastruct. This is L or V shaped. I put it open end down,sanded lightly towards leading edge and more heavily at the trailing edge to make it uniform. Hope this helps. |

| Don C, Image # 35591 | 13 Feb 16 16:20 |

DD, the wheel is 7/16, but it's not a normal one - flat sides and tread with a raised tread on the edge. I think the supplied tailwheel with 1/16 balsa on eachside will give the desired appearance. If it works I'll need one more tailwheel. Thanks for asking. |

| David Duckett, Comment for image # 35581 | 11 Feb 16 17:28 |

| Agree with Poppy! What size wheels do you need? |

| Don C, Comment for image # 35581 | 11 Feb 16 10:21 |

| Since they will be glued in the "up" position it seemed like a waste of time, but to make them look right they need to be built that way. My arthritic fingers thank you for the kind words. |

| Skyediamonds1985, Comment for image # 35581 | 11 Feb 16 09:41 |

| Forgot to also compliment you on your decision to try the pulley route. That's great...!! |

| poppy, Comment for image # 35581 | 11 Feb 16 03:00 |

| Nice bit of engineering there!! |

| Skyediamonds1985, Comment for image # 35579 | 10 Feb 16 23:44 |

| Looks great. At that small scale, they'll look metal and professional. You saved time and money and did a great job. |

| Skyediamonds1985, Comment for image # 35581 | 10 Feb 16 23:43 |

| That's beautiful Don. Congratulations!! I know it's not easy working with small pieces of plastic and good. You've done a remarkable job and shows your level of attention to detail. Job well done, "Mr." Don! |

| rayl, Comment for image # 35581 | 10 Feb 16 21:39 |

| You rate a toddy after that. Looks good! |

| Don C, Image # 35582 | 10 Feb 16 17:28 |

My pin vise. |

| Don C, Image # 35581 | 10 Feb 16 17:26 |

They actually work! Success! Time for a celebratory toddy. |

| Don C, Image # 35579 | 10 Feb 16 17:23 |

Gear pulleys. Paper punch, card stock and 1-16th balsa. |

| Build Thread, Page :

1 2 3 4 5 [ 6 ] 7 8 9 10 11 (212 posts, 20 posts per page, 11 pages in total)

|

[ < Prev ] [ Next > ] |